Our projects

Les Cèdres de Cologny

During the construction of a new residential district in the hills of Geneva, called “Les Cèdres de Cologny”, a surface area of 32,000 m2 was covered with scaffolding. Started in 2014 and consisting of more than 262 housing units, it was the largest housing project in the canton.

The mass of scaffolding, for which ECHAMI was responsible for the assembly and dismantling in less than 30 months, was spread over 11 different towers. Logistics and transport flows accounted for the bulk of our costs, with our teams moving more than 630 tons of equipment for this project.

In addition to providing the supplies and materials, qualified and highly organized personnel were enlisted on-site to match the pace set by the seven cranes and thus ensure the safety of the 300 or so workers present daily.

Download the PDF document

La Dôle

La Dôle, Jura Vaudois. In close collaboration with Sky Guide , we designed and built a spherical scaffold to enable the renovation of the envelope of the air navigation radar at Geneva Airport ✈️.

Thanks to our in-house engineering department and the 3D design of the scaffolding, we were able to build a ‘sphere’ so that La Dôle’s “white ball” could be replaced after more than 20 years of service.

Helicopter-mounted multidirectional equipments 🚁 on-site by Heliswiss International

VEDIA

Located near the Genève-Cornavin train station by the railway tracks, the headquarters of VEDIA, a mail-order company, underwent major renovations on the whole of its two existing buildings (the interior and facade). In addition, a new industrial hall was built.

Due to the architectural complexity of the buildings consisting of a facade with both inclined and Alucobond cassette panels (insulation, substructure and suspended cassette panels), brackets of different depths were required based on a precise layout for the anchors.

On the south side, the proximity to the railway meant work needed to be carried out at night under the supervision of the inspectors of the CFF, the Swiss Federal Railways, to ensure compliance with safety standards, which notably required protective shielding to be erected along the perimeter.

Download the PDF document

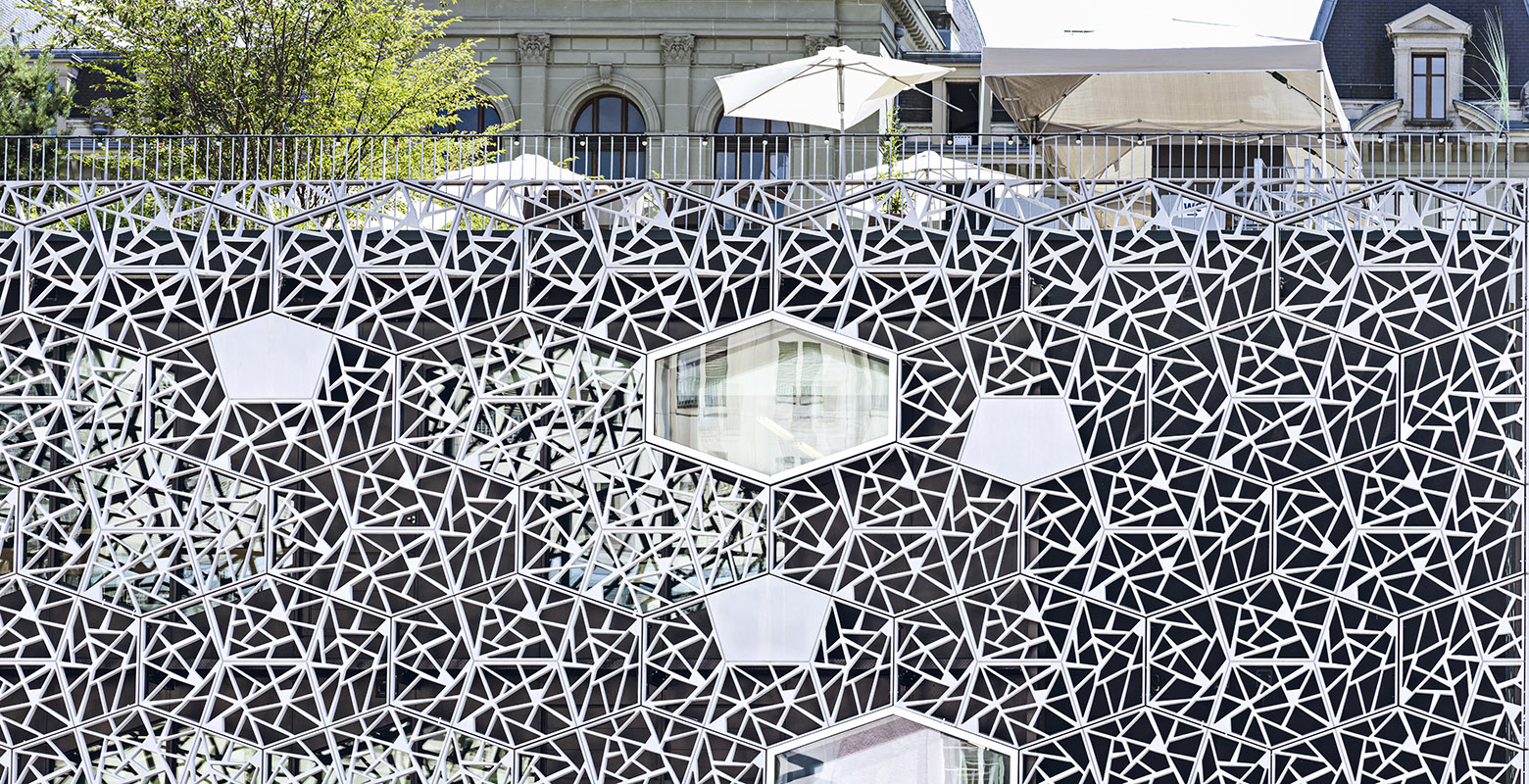

Flon – Pépinières

The “Flon – Pépinières” project brings together three buildings located in the heart of Lausanne. One of the buildings stands out remarkably from the others with its double layers in a perforated mosaic pattern.

On this site, the ECHAMI team had to juggle several different types of scaffolding to manage the complex architecture. Prior to this, a rigorous layout plan for the positioning of the anchors had been made. Lightweight scaffolding, fitted with various safety brackets, was then set up for the facades. Protective barriers inside and on the roof, platforms in shafts, scaffolding in the stairwells, as well as a large range of bridge cranes and service bridges were used.

Finally, in order to enable the cladding specialists to install the second layer, the scaffolding had to be continuously re-adapted as each element was installed.

Download the PDF document

Verbois Dam

Maintenance work was required on the Verbois Dam, notably to replace the bar screens and treat the concrete mullions. The dam was emptied to accommodate the suspended platform structure.

Due to the uncommon dimensions of the structure, difficult weather conditions (night and rainy conditions) and substantial technical requirements, the ECHAMI team had to combine discipline and perseverance until the end of the project. Four teams of builders and two technicians were mobilized, for 24 hours a day over three weeks, to build the platforms suspended along the mullions while the dam was emptied.

These suspended cantilevered platforms, 20 m in height, were carefully arranged around each concrete mullion, enabling the base of the dam to be reached where the bar screens could be cleaned.

The ECHAMI team collaborated closely with its masonry counterparts to adhere to the timed schedule and the precise requirements of the project.

Download the PDF document

Bac 10-12-14

This site in Petit-Lancy is one of the largest building extensions in the canton: it involves four buildings on which two additional floors will be installed. The variable geometry of the buildings, especially the large differences in elevation, contributed to the striking appearance of the project.

Initially split into different stages to facilitate completion, the project was carried out in one go due to timing constraints. Lightweight scaffolding was first put in place to raise and seal the top floor.

Temporary roofing of more than 2,500 m2 was then installed.

Finally, four manlifts, each with a maximum capacity of 2,000 kg were installed, as well as three lifts. One of our operators was allocated on-site for three months to manage the lifts.

Download the PDF document

Le-Sapay School Center

Located in the park of a neighborhood under construction, the Le-Sapay School Center is a school with 24 classes around a vast esplanade, and with a variety of uses: a restaurant, hall, gym rooms, swimming pool, underground passageways, etc.

Aside from the scale of the project, the difficulty of the project stemmed from a set schedule (due to the school year restarting) as well as very tight phases allocated for the various participants in the project.

Lightweight scaffolding (200 kg/m2) including 30 cm safety brackets, had to be set up twice: the first time for the structural work and a second time for the installation of the prefabricated elements. In addition, huge platforms were installed above the swimming pool and for the technical aspects of the gym.

Download the PDF document

Geneva Opera House

Geneva City’s main opera house, the Grand Théâtre, is located in the Place de Neuve, and is one of the most important European opera houses, with its reputation contributing significantly to the cultural influence of the canton of Geneva.

The restoration work carried out on this prestigious monument was quite extensive, first and foremost, its structure and roof. For the facade, very heavy scaffolding (450 kg/m2) was used for the replacement of the dressed stones, for which the scaffolding was tripled in certain areas to cover the wide eaves.

To ensure protection from the elements during flashing and covering, a temporary roof covering more than 5,000 m2 had to be installed. This temporary roof included spans of up to 57 m in length.

Finally, decking of more than 2,000 m2 of various types have been required for the restoration and installation of the suspended structure.

Download the PDF document

WIPO — Conference Room

On the WIPO site, ECHAMI was awarded three major scaffolding lots: the construction of the conference room, the replacement of the facades of the main building and the installation of interior protections during the work.

The conference room, made entirely of a wooden structure with an asymmetric shape extending onto a cantilevered facade (34 m), required the use of triple scaffolding with added safety brackets. To ensure a successful installation of the scaffolding, full tracing on the ground was required to be carried out beforehand. Once the works for the facade were secured, huge platforms were erected inside, some of which were suspended. Several thousand square meters of decking were thus required.

Lightweight scaffolding of 200 kg/m2 was sufficient during the replacement of the facade, the only difficulty being the management of the anchors during each phase.

Finally, for the protection of the interiors, an additional partition was put in place in each office on each floor. A tubular structure was installed to support the panels and insulate the premises, as they remained in use throughout the building works, and thus adding numerous requirements in terms of finishing, cleanliness and timing.

Download the PDF document

Agroscope

For this new Agroscope project, a center of expertise of the Swiss Confederation of Agricultural Research, special scaffolding with a 30 cm bracket had to be set up in the course of the work, ensuring the safety of the masons during the casting of the slabs as well as offering a workable solution to the installation of the double-layered facades. The building is certified as a Minergie P-Eco building under the Swiss sustainable building standard, and a complex coordination of the operations were required, especially during the first phase.

The load-bearing facade was made of wood on which screen-printed glass was affixed. For the second stage, the ECHAMI team carried out a transfer of the anchoring, enabling the final installation of the sub-structure of the facade. Once the wooden frames were slid between the slab heads and the scaffolding, a 250 cm-wide awning was affixed to the top of the scaffolding throughout the periphery to protect the wood frame against the elements. In addition, the glass installation required a final anchoring transfer according to a precise layout and with the use of M12 threaded rods.

The dismantling took place at the end of the project, facade by facade.

Download the PDF document

Biopôle

Biopôle, an eight-hectare science park designed to house companies active in the life sciences sector, provides facilities for industrial, research and development or administrative use. The construction of the first building on the Épalinges campus was led by Losinger-Marazzi taking into account the strict standards applied by Bouygues, a French industrial group.

The scaffolding selected was lightweight (200 kg/m2) and included 30 cm safety brackets. Double scaffolding, completed with a platform under the ceiling slabs was required to handle the huge cantilever located at the north gable.

Finally, in conjunction with the engineers, the dimensions for the shoring were carefully calculated for the attachment of the balcony slab in east facade.

Download the PDF document

International Labor Office (ILO)

An emblematic building in Geneva due to its imposing size (44 m high and 200 m long) and rounded architecture, the ILO is perched like a mainsail in the hills of the United Nations neighborhood. Major renovations and restoration to present standards are currently underway, with the facades in particular needing restoration to improve the thermal performance of the building, while also maintaining its original appearance given its status as a listed monument.

In this regard, several complex and interdependent issues had to be solved: the colossal dimensions, placing the entire scaffolding on a load-bearing bracket, an anchoring system in listed facade shells or managing the continuous flows of equipment and people.

Our technical office carried out numerous calculations beforehand to determine the suitable scaffolding (lightweight with a 30 cm bracket) and the maximum frame that could be used at such a height. Our engineers also calculated the choice of carrier brackets (sizing) and their anchors. In addition, the anchoring solution was developed by our mechanical workshop where special parts were produced due to the site type.

For the transport of people, we opted for four fast lifts that could accommodate up to 14 people and selected six freight elevators for goods with a maximum capacity of 2,000 kg. Additionally, receiving platforms for the transit of goods were set up.

Download the PDF document